|

| Sir David Brown and DB6 |

When most

people think about Aston Martin, they think about a hand-made English sports

car produced at Newport Pagnell. The more knowledgeable would know of their

origins as Bamford & Martin in Kensington, followed by a period in Feltham.

Others may know of the firm's association with Touring of Milan and of the

wonderful and stylish cars that were produced as a consequence. Few however

could imagine that without the small Yorkshire town of Huddersfield, none of

this would have happened.

This is a

blog relating to a Northern Powerhouse nestling in the Pennines.

In February

1947 the Huddersfield industrialist David Brown bought Aston Martin Ltd. from

Gordon Sutherland and Claude Hill for the sum of £20,000. Later that year he

also purchased Lagonda for the sum of £52,500, as he was interested in a new

engine that had been designed for the company by W.O. Bentley. He felt that this 2.6 litre DOHC engine would

be ideal in his new sports car the DB2.

In 1955 he

bought Tickford, the coachbuilding company started by Salmons & Sons and

based at Tickford Street, Newport Pagnell. David Brown

was not just a wealthy and astute industrialist; he had both an appreciation of

engineering in general and a keen eye for motor cars. It was his wish to produce

the finest sports-car in the world.

His purchase

of Aston Martin in 1947 heralded the dawning of a Golden Age for the marque and

their continuing association until 1972 resulted in the finest hand-made cars

to have ever passed through the factory gates. He also turned AM in to a winner

on the race tracks, with a LeMans victory and the World Sports Car

Championships in 1959.

In 1961

David Brown Industries employed a work-force of over 7000, with factories in

Huddersfield, Coventry, Manchester, Salford and London. The company also bought

a controlling share in shipbuilders Vosper Thorneycroft in 1964 and had

factories and business interests throughout the world.

The Company

badge of DB with a white and red rose says it all. This was a town at the sumit

of the Pennines, with Lancashire to the west and Yorkshire to the east. From Farsley

in the north to Peniston in the south, virtually the whole of the town and

surrounding area came under his influence.

To list but

a few:-

Lockwood Head Office

Park Works – Swan Lane Heavy gears/boxes/heat

treatment

Keighley Gears – Howarth Lane Radicon/reduction units

Meltham Mills Tractors

Peniston – Green Road Foundry/pumps

Aspley - St. Andrews Road Forge/fabrication/chassis

shop

Scholes TrainingSchool/AdvanceTraining/R&D

Newlands Works – Farsley Tractor/LB6

engines/DB2/4 assembly line

Forward

thinking as ever, he also had his own private airfield at Crossland Moor, one

of the slightly less hilly parts of the town from which he would fly his De

Havilland Dove to business operations further afield. Invariably he would be

accompanied by at least one glamorous assistant and this was well before the

advent of the PA.

I came

across a very nice brochure relating to the DB6 the other day entitled ‘A

Living Legend’.

I would like to share with you the contents of this publication, partly because it is a great period piece from Aston Martin but mostly because it shows just how much they cared about their product.

It was very pleasing to note that the chassis were transported to Newport Pagnell by road from David Brown Industries in Huddersfield. Indeed they were fabricated in the chassis shop at St. Andrews Road, Aspley situated between Broad Canal and the river Colne.

|

| St. Andrews Road Works |

If you accept that the chassis is the bones of a car, it is certainly nice to know that it was made in Yorkshire. It also shows how committed Aston Martin was under David Brown to make the ‘complete car’. Even their great rivals Ferrari at that time had their chassis made by Vaccari in Modena.

Quote: 'The body is

hand formed from 34 separate 16swg alloy panels, welded together to make the

shell. A steel wire surround is lipped into the lower edges of all sections to

give added strength. All dents and ripples are hand beaten out before being

passed to the paint shop, where between 20 and 22 coats of primer and final

colour are applied to each car'. Wonderful stuff.

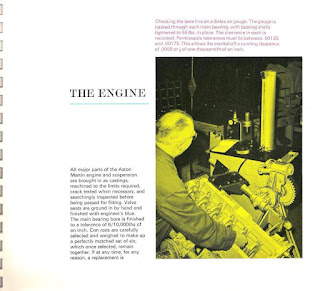

Then we come

to the engine.

Well if the

chassis is the bones of the car, then the engine is its heart.

The

wonderful thing about Aston Martin at this time is that they truly made their

own engines. From raw castings and forgings, everything was machined and

assembled in-house. After all, how could a car manufacturer that did not make

his engine be taken seriously? This was the failing of Jensen and Bristol for

example, well made and stylish cars but with a bought-in and mass produced

engine.

What is

apparent from the brochure is the level of care and pride that went into the

building of these engines at Newport Pagnell.

The seven main bearing bores within the crankcase are line-bored on a DIXI/Le Locle jig-boring machine to a tolerance of 0.0006 of an inch, impressive stuff indeed when you consider the length of this crankcase. These machines were hand operated and reliant entirely on the skill of the operator. The crankshaft is balanced statically and dynamically, initially on its own then with the flywheel attached. The con-rods are weighed and selected to make up a perfectly matched set of six. The same is done with the pistons and gudgeon pins, all to ensure a perfect balance throughout.

The seven main bearing bores within the crankcase are line-bored on a DIXI/Le Locle jig-boring machine to a tolerance of 0.0006 of an inch, impressive stuff indeed when you consider the length of this crankcase. These machines were hand operated and reliant entirely on the skill of the operator. The crankshaft is balanced statically and dynamically, initially on its own then with the flywheel attached. The con-rods are weighed and selected to make up a perfectly matched set of six. The same is done with the pistons and gudgeon pins, all to ensure a perfect balance throughout.

The engine

is solely built by one fitter, the attention to detail so great, that the

tester can tell who this individual was by the performance on the brake. All

engines are run at varying speed up to a limit of 5,500 rpm for 4 ½ - 5 ½ hours using a Hennan & Froude dynamometer.

Of course David

Brown had a long history of building engines at the Newlands Works, Farsley just

north of Leeds. The tractor engines were built there as was the Lagonda

designed LB6 fitted to the Aston Martin DB2 onwards. In fact a production line

was introduced at the factory in 1953 for the new DB2/4 model. Almost all these

cars were assembled in this factory before being driven to Feltham for final

inspection. The factory closed in 1957 at the end of the model run and the car engine

production with many of the engineers moved to Newport Pagnell.

|

| DB2/4 assembly line Newlands Works |

Not only did

Aston Martin produce their engine in house, but David Brown Industries

manufactured many of the machines and much of the tooling used in production.

From gear planing machines to floating reamers, they made them all.

|

| Newlands Works Farsley |

Back to the brochure.

After the

car is completed and has passed all its tests, it is driven for at least 100

miles of solid workout. It is then given a final coat of paint and the bumpers

fitted, only then is it passed to Sales for distribution. A total of 1200

working hours or three months will have passed since the steel platform chassis

arrived at the factory. This is how long it took to make an Aston Martin DB6.

So what have we learned from reading this period literature?

Well there was clearly no raiding of the corporate ‘parts

bin’ here. No use of a chassis/platform

designed and used previously by another car maker. No use of an out-sourced engine

produced in the factory of a mass car manufacturer. No these were hand made cars

through and through.

That is not to say that specific parts were not sought

elsewhere if they were considered to be the best available products of the

time. Examples of this are the Salisbury back axle, 5 speed ZF gearbox and

power steering components used on the DB6. Oh and the track-rod ends from a

Coventry Climax fork lift truck.

As always

perfection does not come cheap.

In 1965 the

model was launched with a UK recommended retail price of £4,998, all

Alternative Equipment being available within that cost. In July 1966 the Wilson

government increased purchase tax and clamped down on hire-purchase tax

concessions, which lifted the retail price to £5,085. This and the overall

economic uncertainty of the time resulted in a distinct lack of orders. David

Brown took the drastic decision to reduce the price of his cars and by 1967 a

£1000 had been knocked off the original list price. There is an often repeated story

that relates to the DB6, in that David Brown at a business lunch in London was

approached by an old friend and asked if it would be possible as a favour, for

him to purchase a car at cost. David Brown replied he would be delighted to

oblige and several days later the friend received an invoice for a £1000 more than

the published list price.

True or not,

it is a lovely story and one any Yorkshireman would be proud of.

I would like to leave you with a few sentences from the front page of the brochure.

‘Each car is an individual achievement of dedicated men;

hand-built with imagination, skill and superlative craftsmanship. The Aston Martin

is a living legend – and the legend will continue as long as pride in

workmanship, awareness of real distinction in design and appreciation of truly

beautiful things persist’

What

sentiment.

A living legend indeed.

No comments:

Post a Comment