This short blog is to be the first related to a hugely talented racer from the North East who did things a little differently than most: namely Ken Redfern.

This post is in relation to the trophy named in Ken’s honour.

Ken’s life was tragically cut short in 1973 after a freak road traffic accident. Four or five weeks after the accident about 20 of Ken’s family and friends had a meeting at a local restaurant to honour Ken. From the meeting it was decided that in order to perpetuate Ken’s name with the sport he so loved, a trophy should be made and awarded annually; the Ken Redfern Trophy.

|

| Ken Redfern Trophy with Ken's helmet |

The design of the trophy was to replicate the logo on Ken’s helmet; a wild goose flying through a laurel wreath. The use of these two symbols were due to Ken's biggest passions in life: wildlife and motorcycle racing.

A trust was set up in the autumn of 1973 to help cover the cost of manufacturing the one-off trophy which allowed friends, family and fans to donate any amount into.

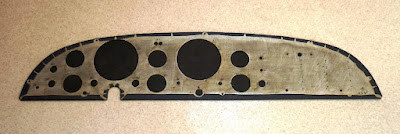

Middlesbrough Art College was given the task of designing the trophy. As part of this they manufactured a resin mould which would be used by a foundry to cast the trophy. Prior to Christmas 1973 an initial resin mould had been prepared and was shown to Ernie and Mike Redfern (Ken’s Dad and younger brother). A few small modifications were made following this review to allow the moulds to be completed. For the design and manufacture of resin models Middlesbrough Art College charged £1000. It was now time to find a suitable foundry.

After much research by Ernie Redfern a suitable foundry was selected: Morris Singer foundry in Basingstoke. They were the oldest fine art foundry in the UK and dated back to 1848. Notable artworks cast by Morris Singer include Jacob Epstein's "St Michael's Victory over the Devil" for Coventry Cathedral and the Single Form sculpture situated outside the UN by Barbara Hepworth.

Morris Singer foundry cast the trophy using the moulds; the laurel wreath out of copper and the wild goose out of 925 Sterling silver. The Morris Singer Foundry charged £2500 for casting the trophy.

.jpg) |

| Ken Redfern Trophy |

The total weight of the metals in the trophy was a whopping 11.7kg! When put on a plinth the total weight was 13.5kg.

In more recent times the silver was tested and hallmarked by the Sheffield Assay office.

The North East Motor Cycle Racing Club (NEMCRC) were given custody of the Trophy and from that point onwards. Annual meetings were held. Ken's Trophy was first competed for in September 1974 at the Croft Circuit. The meeting was on Saturday 21st September and was a National meeting arranged by the NEMCRC. Race 7 at the meeting was the Ken Redfern Invitation for motorcycles of 250cc-1000cc which was held over 10 laps. There was a who’s-who list of donors for the prize money for the Ken Redfern Invitation, which included Paul Dunstall, Motor Cylce News, Motor Cycle magazine, Les Siddle (Lamplas fairings), Eddie Johnson, Dennis Pratt, Armstrong motorcycles, Keith Jeal (Ken’s mechanic) and Mike Redfern.

Big prize money was 'up for grabs' at the meeting to ensure a good grid entry with bonus awards for:

- The leader at the end of each lap

- The fastest lap

- The winner and cash down to 10th place

This incentive attracted the country's top riders for 50 years.

|

| 1974 programme cover |

|

| Entrants for 1974 Ken Redfern Invitation Race |

The riders who entered up for the first Ken Redfern Invitation race in 1974 included top names such as Mick Grant, Roger Marshall, Steve Tonkin, Phil Gurner, Stewart Hodgson, Paul Cott, Austin Hockley, Tony Myers, John Webb, George Fogarty and a future World Champion from South Africa Kork Ballington. The race was won by Kork Ballington who led from the first lap to the chequered flag. Finishing behind Kork was Phil Gurner, Roger Marshall, Paul Cott, Austin Hockley and John Webb completing the top six finishers.

|

| 1974 and 1975 winner Kork Ballington with Ernie Redfern |

The Ken Redfern trophy was competed for every year until the final running of the race in 2023 (apart from 2020 and 2021 due to COVID). Other notable winners of the Ken Redfern trophy include Roger Marshall, Steve Manship, Steve Henshaw, Joey Dunlop, Jamie Whitham, Ian Simpson, Jim Moodie, David Jefferies and John McGuinness. The full list of winners is presented at the end of the article.

|

| 1976 winner Roger Marshall with Ernie Redfern |

|

| 1984 winner Joey Dunlop with Mike Redfern |

|

| 1988 winner Dave Leach with Mick Grant |

The trophy currently still resides with the family, however, the time has come for it to look for a new long-term home either still linked to the sport or in a suitable private collection. If anyone has a serious interest I can put interested parties in contact with the family.

List of race track’s which held the annual meeting:

- Croft Circuit 1974 - 1981

- Oliver’s Mount Scarborough 1982 - 1989

- Knockhill 1990 - 1999

- Croft Circuit 2000 - 2023

|

| Trophy winners up to 2009 |

List of past winners of the Ken Redfern Trophy:

- 1974 - Kork Ballington

- 1975 - Kork Ballington

- 1976 - Roger Marshall

- 1977 - Steve Wright

- 1978 - Steve Manship

- 1979 - Graham Wood

- 1980 - Steve Manship

- 1981 - Graham Wood

- 1982 - Steve Henshaw

- 1983 - Mark Salle

- 1984 - Joey Dunlop

- 1985 - Mark Salle

- 1986 - Mark Phillips

- 1987 - Dave Leach

- 1988 - Dave Leach

- 1989 - Jamie Whitham

- 1990 - Brian Morrison

- 1991 - Ian Simpson

- 1992 - Jim Moodie

- 1993 - Jim Moodie

- 1994 - Andrew Stroud

- 1995 - Brian Morrison

- 1996 - Dean Ashton

- 1997 - Nick Jefferies

- 1998 - David Jefferies

- 1999 - Dean Ashton

- 2000 - John McGuinness

- 2001 - Dennis Hobbs

- 2002 - Dennis Hobbs

- 2003 - Dennis Hobbs

- 2004 - Dennis Hobbs

- 2005 - Keith Pringle

- 2006 - Kirk Jamison

- 2007 - Gavin Littlewood

- 2008 - Kirk Jamison

- 2009 - Joe Burns

- 2010 - Jimmy Storrar

- 2011 - David Paton

- 2012 - Andrew Tasker

- 2013 - Barry Teessdale

- 2014 - Barry Teessdale

- 2015 - Lee Wilson

- 2016 - Andrew Tasker

- 2017 - Lee Wilson

- 2018 - Barry Teessdale

- 2019 - Mikey Evans

- 2020 - COVID (no event)

- 2021 - COVID (no event)

- 2022 - Richard Evans

- 2023 - James Alderson

.jpg)