This is a

blog based around a second edition of the Hepolite brochure.

This 135 page brochure was published by Hepworth & Grandage Limited in the early 1960s and gives an insight and description of the products made. Hepwoth & Grandage were manufacturers of internal combustion engine components and were situated in and around Bradford, West Yorkshire. They formed part of an elite group of companies known as AE or Associated Engineering Limited.

| |

| A selection of Hepolite products |

The four

plants employed in the manufacture of these internal combustion engine

components, together formed the largest manufacturing unit of its kind in the

world. A total workforce approaching 5,500 produced the most comprehensive

range of pistons, rings and liners available throughout the world.

| |

| Hepolite plants in Yorkshire |

When reading

the brochure it is wonderful to note that everything was done in-house.

From design

to drawing office, from pattern shop to foundry and from heat-treatment to

inspection, every stage required to complete a component was done within those

factory walls. This required a highly skilled workforce, especially in the

areas of Design & Drawing Offices, Pattern-making, Jig & Tool Rooms and

Inspection Department.

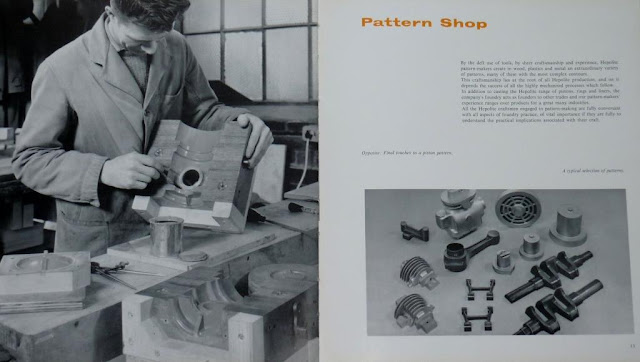

I quote: “By

the deft use of tools, by sheer craftsmanship and experience, Hepolite

pattern-makers create in wood, plastics and metal an extraordinary variety of

patterns, many with the most complex of contours. This craftsmanship lies at

the root of all Hepolite production and on it depend the success of all the

highly mechanised processes which follow.”

| |

| Pattern making |

The foundry

is an early and key stage of component manufacture.

This facility

has continually expanded over the years and at the present time has a weekly

output of some three hundred tons of finished castings. Several years ago the

company took out a licence with the International Nickel Company to produce

spheroidal graphite cast-iron, which is now being used in the production of

many engineering castings for the motor and other industries. A centrifugal

casting foundry was opened in 1938 and has been developed continuously ever

since. This section employs considerable mechanisation, the metal being melted

in high frequency induction furnaces and the plant operates both day and night.

| |

| Piston ring foundry |

The large

scale manufacture of pistons to suit all different types of internal combustion

engines, compressors, pumps and hydraulic units in use today is a vast problem.

Quantities may vary from a single unit, to thousands of a single design and in

a minimum of five oversize options. In the production of these pistons,

conventional machine tools are used for the straightforward operations, but the

more complex and specialised machining is undertaken on equipment specifically

designed and built by Hepolite engineers. Each process is almost entirely

automatic and carried out on modern or special machine tools under very close

control, meaning an unusually high degree of precision and uniformity are

achieved.

| |

| Piston machining department |

Now here is

a most telling chapter; the Apprentice Training School.

Again I

quote: “The cry in the engineering industry has always been for young men, properly

trained, to keep British industry in the forefront of world development. In

building the Apprentice School and equipping it with the finest machines of

their type, Hepworth & Grandage have made a valuable investment. For the

apprentices trained there will provide the future craftsmen, technologists and

managers to operate our factories in Bradford, Yeadon, Saltaire, Leeds and

Sunderland.”

Well said.

| |

| Apprentice school |

So after a

day packed with enterprise and hard work, what happens in the evening you ask? The

Sports and Social Club of course. If a member of the Company wishes to take

part in some strenuous pastime, he has football, cricket, table-tennis,

swimming and Judo from which to choose. If however his pastime is of a more

relaxed nature, then it’s off to the club for a game of billiards, darts or

chess. All of which can be enjoyed in the pleasant surroundings of the

fully-licensed club-house.

| |

| "A half of bitter please" |

At this

period in time Hepolite were undoubtedly world leaders in the design and

manufacture of pistons, liners and associated components. They accepted this

responsibility very seriously indeed and promoted good practice and custom at

every available opportunity. Below is the fourth edition of their Service

Manual, published in January 1961.

This is a

very concise and well described 128 page manual relating to both general good

practice and the use of their components in internal combustion engines. As

they were selling a quality product, it was clearly in their interests to

ensure these were correctly selected and fitted at all times. Reputation was

paramount to Hepworth & Grandage and they went to great lengths to ensure

that things were done correctly, both during manufacture and in subsequent

fitting by an outside contractor.

This is

where King Hep had his say…..in all cases however trivial, be thorough and DO

THE JOB RIGHT.

| |

| King Hep |

Hepolite

clearly realised the value of publicity and were actively involved in many

forms of motorsport. From providing ‘one-off’ pistons for development and

experimental engines, to proving sponsorship to those riders and drivers that

used their products on race tracks around the world.

| |

| Alistair King's badges |

As

motorsport is a fiercely competitive discipline and with those involved

constantly seeking an advantage or gain over their rivals, engine builders and

‘tuners’ would not wish to make the results of their efforts known. In

supplying unfinished pistons to these teams and individuals, Hepolite were able

to claim credit for their product and yet the ‘tuners’ were able to keep their

modifications a secret. It clearly worked favourably for both parties and most

of the top runners would work with them in this way.

| |

| Partly finished and used Manx Norton pistons |

| |

| Unmachined and as used piston crowns |

Sadly the

great firm of Hepworth & Grandage Limited no longer exist. In 1983 they

became Extrudex Products Limited, then in 1989 AE Piston Products Limited

before finally closing the factory gates in 2002.

So what of

Helpolite now?

Wassell

Limited bought the ‘Hepolite’ tradename from the Federal-Mogul Corporation in

2011 and started selling‘Hepolite’ pistons manufactured by Jieh Chueng

Industrial Co Ltd in Taiwan. This is a company specialising in aluminium

casting and precision machining, the pistons they produce commonly go by the

name of JCC.